1. GBD - Grain Boundary Diffusion

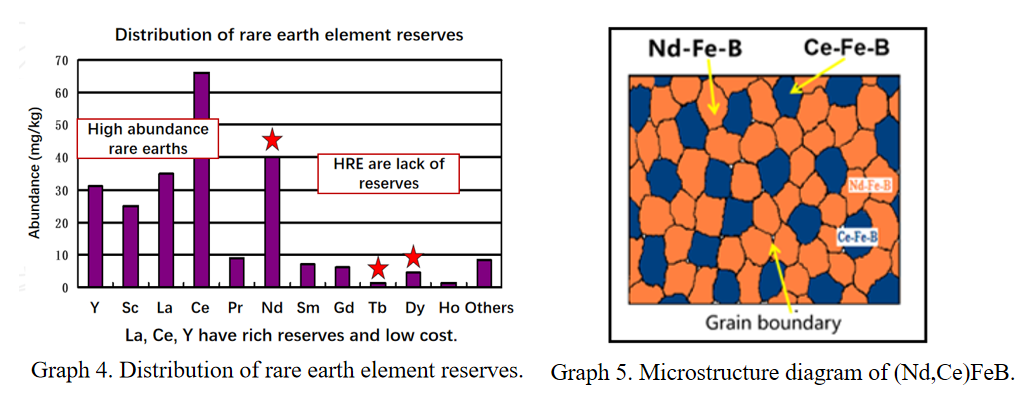

GBD technology is the most effective method to enhance magnetic performance with small amount of heavy rare earth elements. The process is carried out between the machining process and surface treatment process. The process and mechanism diagram are shown in Graph 1.

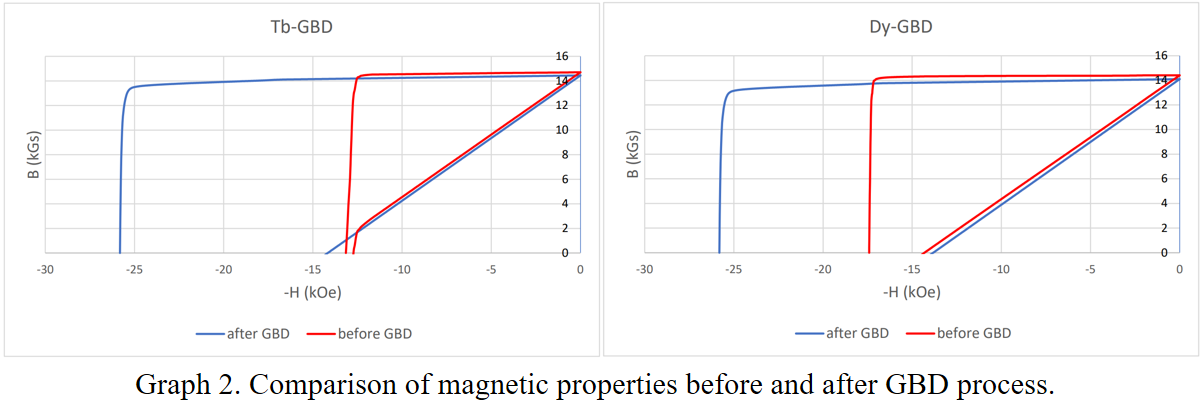

Putting the material containing HRE (Dy or Tb) onto the surface of NdFeB magnet, the HRE will diffuse from surface to the inner space of the magnet during the high temperature treatment. The grain boundary will be reached with Dy or Tb and the coercivity of the magnet enhanced. The BH curves are shown in Graph 2, significant increase of the coercivity of the magnet after GBD treatment is visible.

GBD process can be realized in different ways depending on the geometry-shape of magnet. DMEGC possess the most mature GBD technologies:

1.Spray technology

2.Adhesion technology and

3.Physical Vapor Deposition - PVD technology

DMEGC can produce magnets using both Dy and Tb - GBD, depending on material grade.

1.Advantages of GBD Technology

1)Significant increase of the coercivity which cannot be achieved by conventional process able preparation of the materials resistant to the very high temperature - ultrahigh grades.

2)Significant reduction of heavy rare earth elements and therefore cost. Magnets are more

2. Heavy Rear Earth – HRE Technology

There are two types of the HRE Technology, Less HRE & HRE Free Technology. Aim of these technologies is to reduce the amount of HRE in magnets, on this may cost will be reduced and magnets will be more environmentally friendly. Less HRE & HRE Free Technology is carried out by properly composition designing of material, refining particle size, and improving distribution of magnetic powder, controlling the grain size of material and distribution of grain boundary, to achieve high performance without or using less heavy rare earth elements (Dy, Tb). The equivalent performance will be obtained compare with conventional heavy rare earth process by using less amount of Dy or Tb. This technology is suitable to produce mid and low material grades.

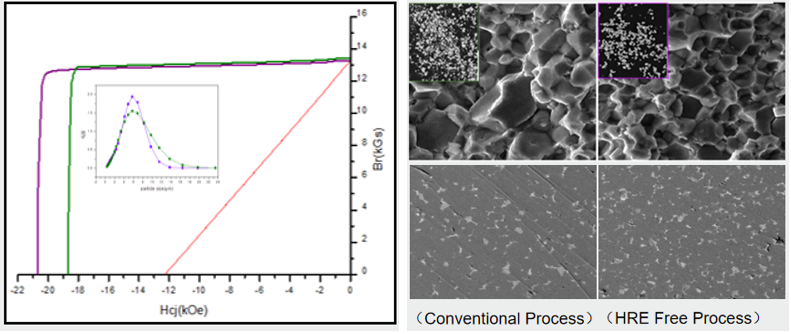

Graph 3 shows the material characteristics of conventional and HRE free process. Compared to conventional process, the product prepared by HRE free process shows better particle size consistency, and smaller grain size, therefore higher coercivity.

Graph 3.Comparison of powder distribution, grain size and coercivity between products prepared by conventional process and HRE free process. Green line: conventional process, purple line: HRE free process.

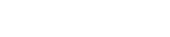

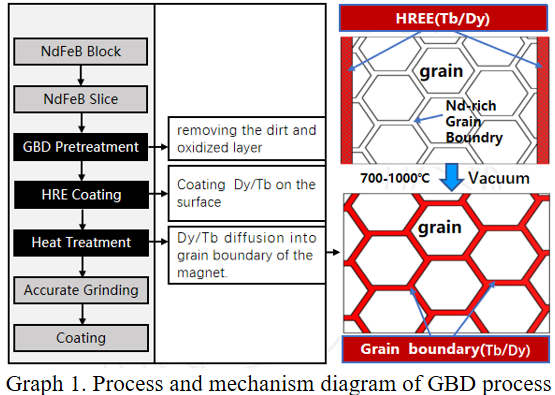

3. Ce Replacement Technology

The relatively cheap and high-abundance rare earth element Cerium-Ce, see the Graph 4, is used to partially replace Nd in the material, see the Graph 5. On this way reduction of Nd amount in the material will lead to the cost saving as well as to the realization of the balanced utilization of rare earth elements.