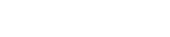

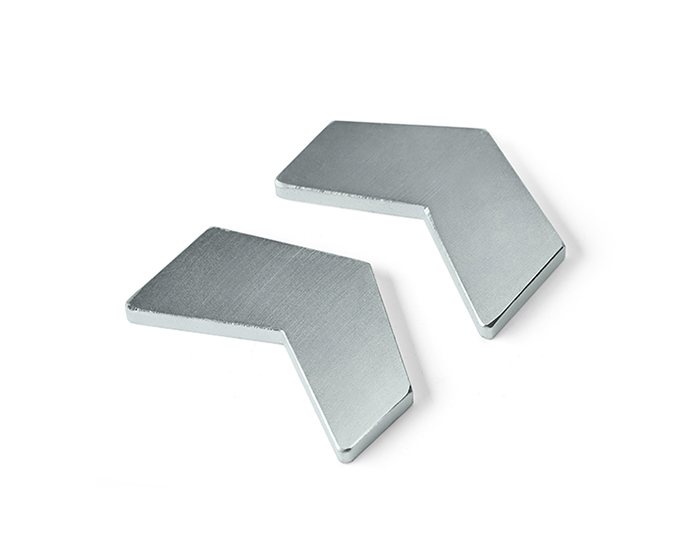

Sintered NdFeB materials are widely applied in many areas of industry and life due to high permanent magnetic performances and high cost-effectiveness. Sintered NdFeB permanent magnets have excellent magnetic properties: very high residual flux density (Br) and magnetic energy density (BHmax), and coercive field strength (HcJ) and working temperature. So sintered NdFeB magnets have small size and high magnetic performance because of their ultrahigh permanent magnetic properties. Therefore, they are the best choice for the devices and motors concerning the size, with the small magnets one can achieve high magnetic power.

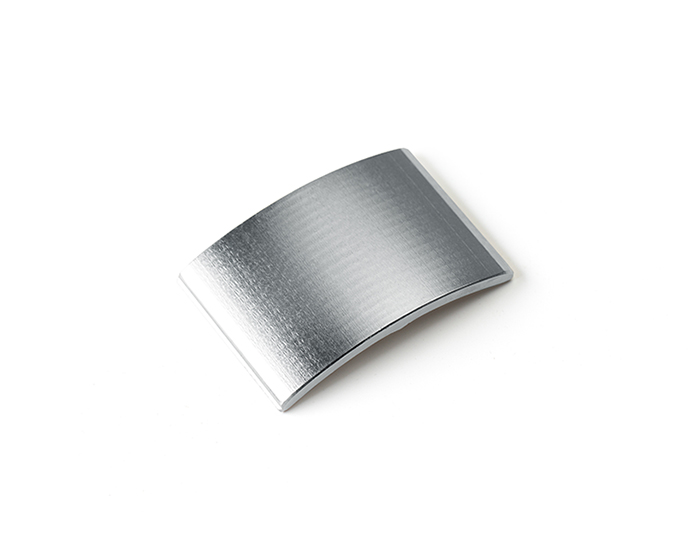

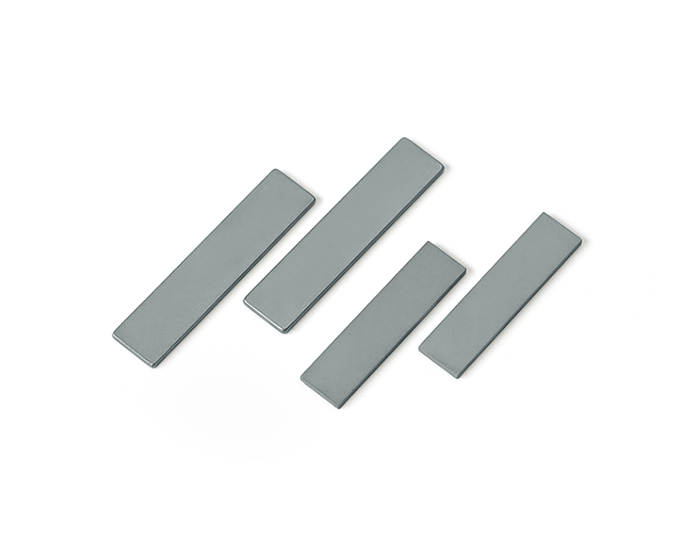

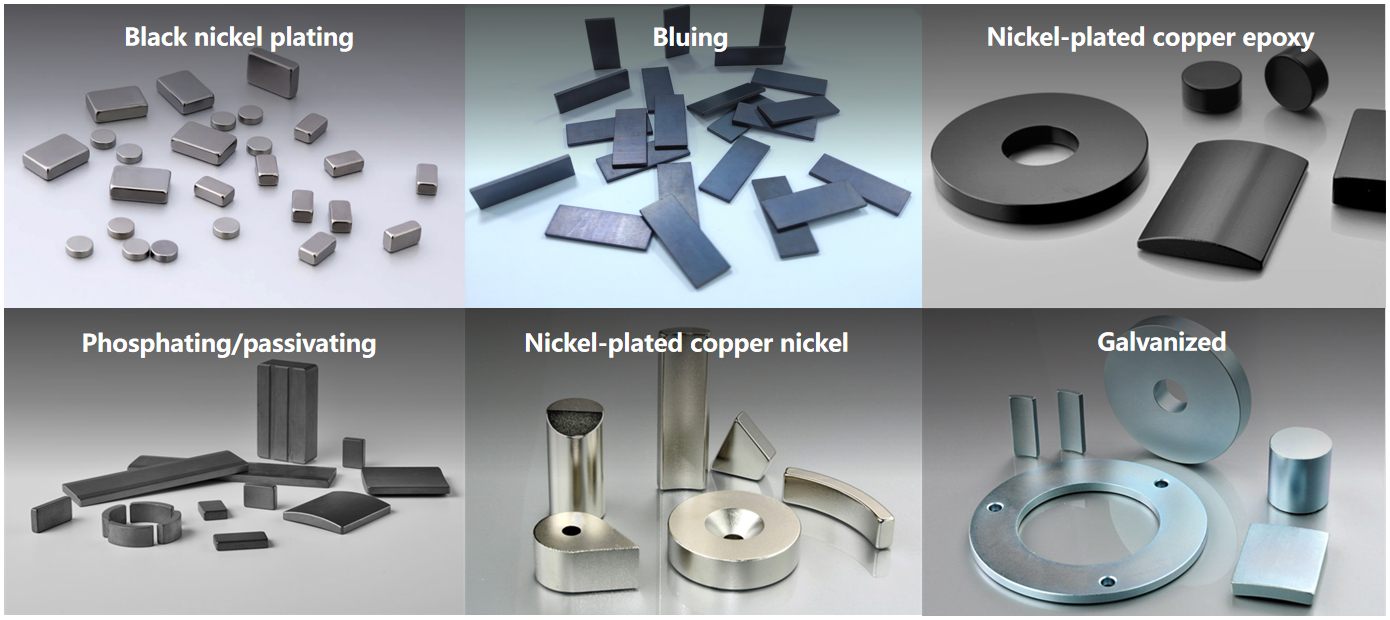

Sintered NdFeB magnet contains Nd, Fe and B which form the main phase Nd2Fe14B, and small amount of some other elements, such as Dy, Tb, Co, Al, Cu, Zr, etc., used to adjust its structure and magnetic properties. The material has polycrystalline structure and are manufactured by powder metallurgy process. Magnets are prepared by multi-machining processes and thereafter have usually surface treatment.

| File Name | |

|---|---|

| Website technical information of NdFeB -240112 English-krl.pdf | PDF |

| GBD-effect.pdf | PDF |

| BH-Curves of N52H and N42SH-HRE | PDF |

| BH-Curves of N45AH, N50EH, N52UH, N54SH and N48UH | PDF |

| BH-Curves of N35, N38M and N40H | PDF |